Features

Precision Welding Without the Hassle

The Cobot Weldspace® ensures uniformity and accuracy in every weld by automating crucial parameters such as speed, heat input, and shielding gas flow. This enhanced welding precision eliminates inconsistencies, reduces defects, and minimises reworks, ultimately leading to higher-quality results with less manual intervention.

Simple, User-Friendly Automation

Designed to make automation accessible, the Cobot Weldspace® features an intuitive programming interface that allows users to set up workflows with ease. Its drag-and-drop controls remove the need for complex coding, making it a perfect solution for both experienced welders and those new to robotic welding. This simplicity enables quick adoption and seamless integration into existing workflows.

Continuous Workflow with Parallel Shuttle Operation

The Parallel Shuttle Operation feature ensures a continuous workflow, significantly reducing bottlenecks. While welding takes place on one side of the workspace, the next job can be prepared simultaneously on the other. This efficiency keeps the system running without interruptions.

Automated Torch Cleaning for Uninterrupted Performance

Torch maintenance can be a time-consuming and disruptive process, but the Cobot Weldspace® eliminates this issue with its Integrated Torch Cleaning Station. By automatically removing spatter buildup, the torch remains in optimal condition, improving weld consistency and extending equipment longevity. This results in fewer maintenance interruptions and a more reliable welding process.

Enhanced Safety Without Compromising Efficiency

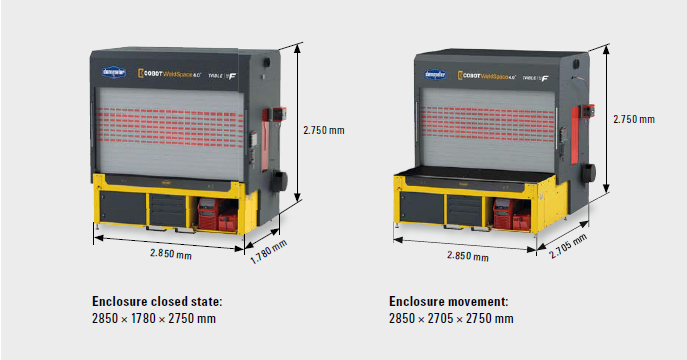

Safety is of the highest priority in welding environments. The Protective Enclosure and Viewing Area shields operators from sparks, fumes, and UV radiation while still allowing clear visibility of the welding process. By maintaining compliance with safety regulations and reducing exposure to hazardous elements, the system creates a secure workspace.

Reduce Costs & Maximise Profitability

By lowering energy consumption and minimising material waste, Cobot Weldspace® helps manufacturers control expenses while maintaining consistent, high-quality welds. Automation also accelerates project completion, ensuring companies can take on more work without increasing labour costs.