Features

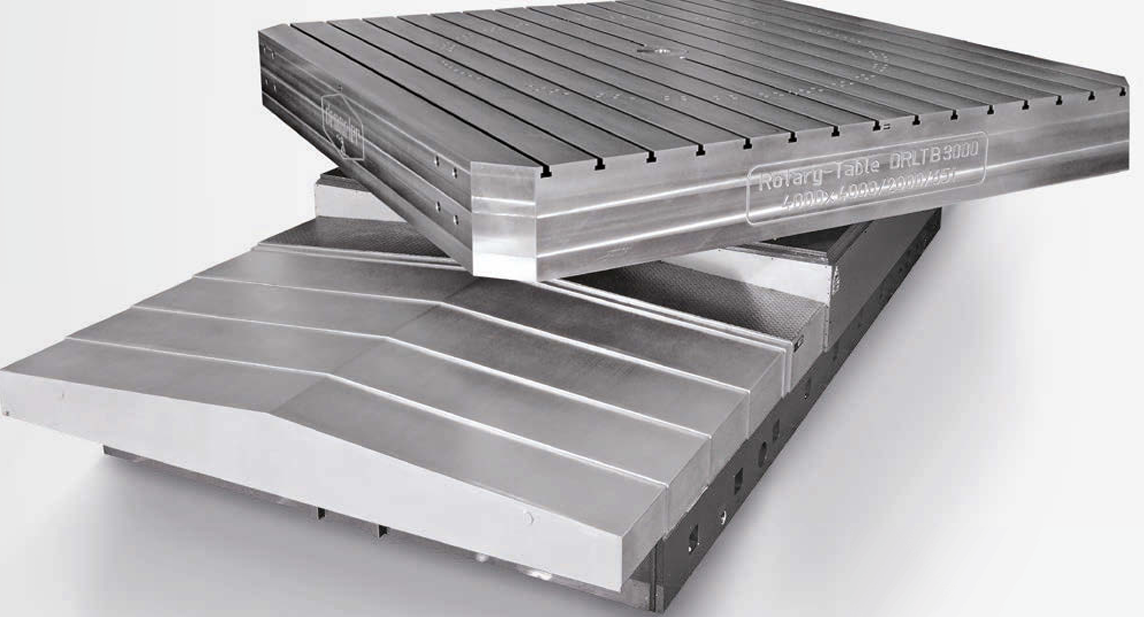

Exceptional Precision & Repeatability

Demmeler Rotary Tables eliminate inaccuracies with cutting-edge motion control and high-rigidity construction, ensuring perfectly aligned machining every time.

Built for Heavy-Duty Machining

Demmeler Rotary Tables are engineered for loads ranging from 5 to 500 tonnes. Their robust design maintains stability under extreme torque loads, making them ideal for machining steel, titanium, and cast-iron components.

Hydrostatic Bearing System for Wear-Free Performance

Traditional rotary tables suffer from friction and wear over time. Demmeler’s Hydrostatic Bearing System eliminates direct contact between surfaces by introducing a pressurised fluid film. This results in zero wear, reduced vibration, and extended equipment lifespan, ultimately minimising costly downtime.

Plug-and-Play CNC Integration

Installing new equipment often leads to workflow disruption, but Demmeler Rotary Tables feature a standardised Plug-and-Play interface. This allows for seamless integration into CNC machining centres and automated production lines.

Optimised for Industry 4.0 & Smart Manufacturing

With integrated measuring systems, smart sensors, and real-time data monitoring, Demmeler Rotary Tables are fully Industry 4.0-ready. Their high-precision encoders and automated adjustments enable predictive maintenance and continuous accuracy tracking, helping manufacturers optimise efficiency.

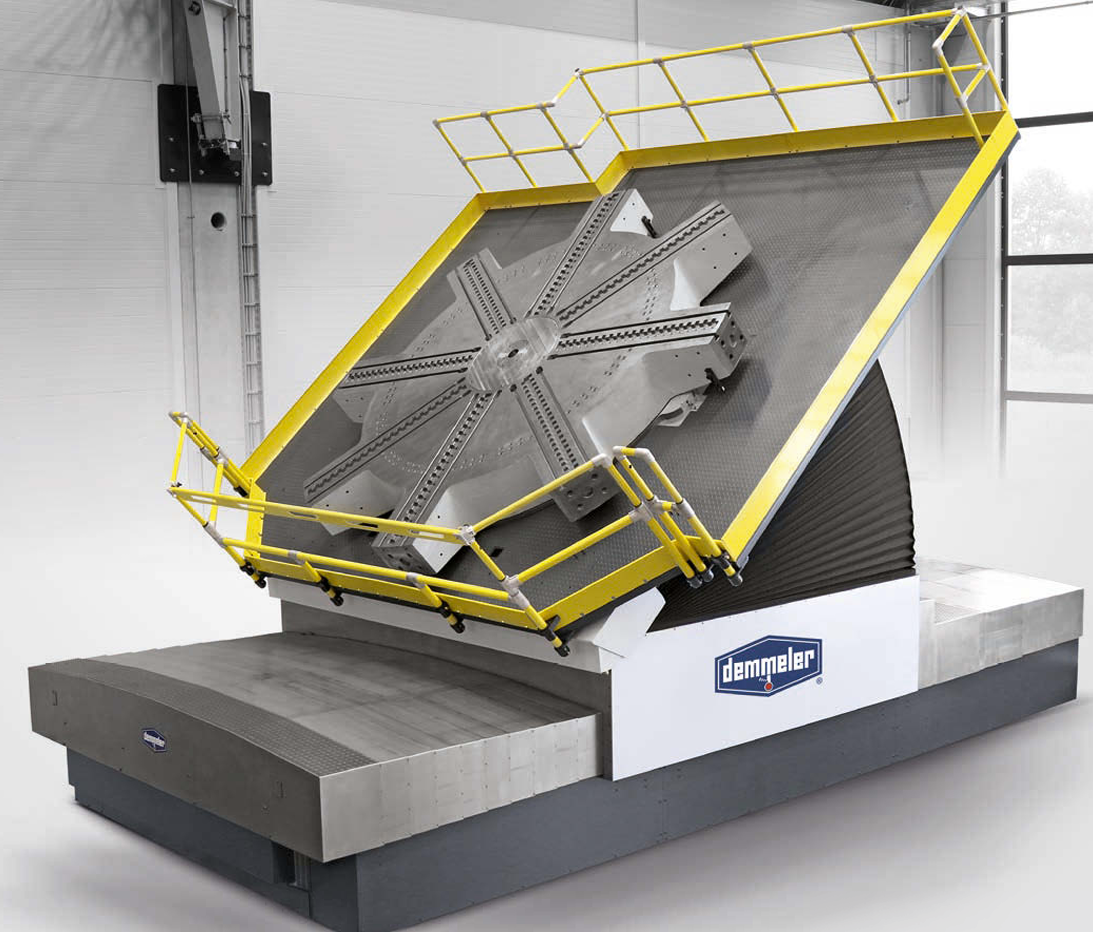

Flexible Tilting & Multi-Axis Motion

Demmeler Rotary Tables feature tilting axis adjustments up to 90°, ensuring optimal tool approach angles for improved machining precision in aerospace, automotive, and industrial applications.